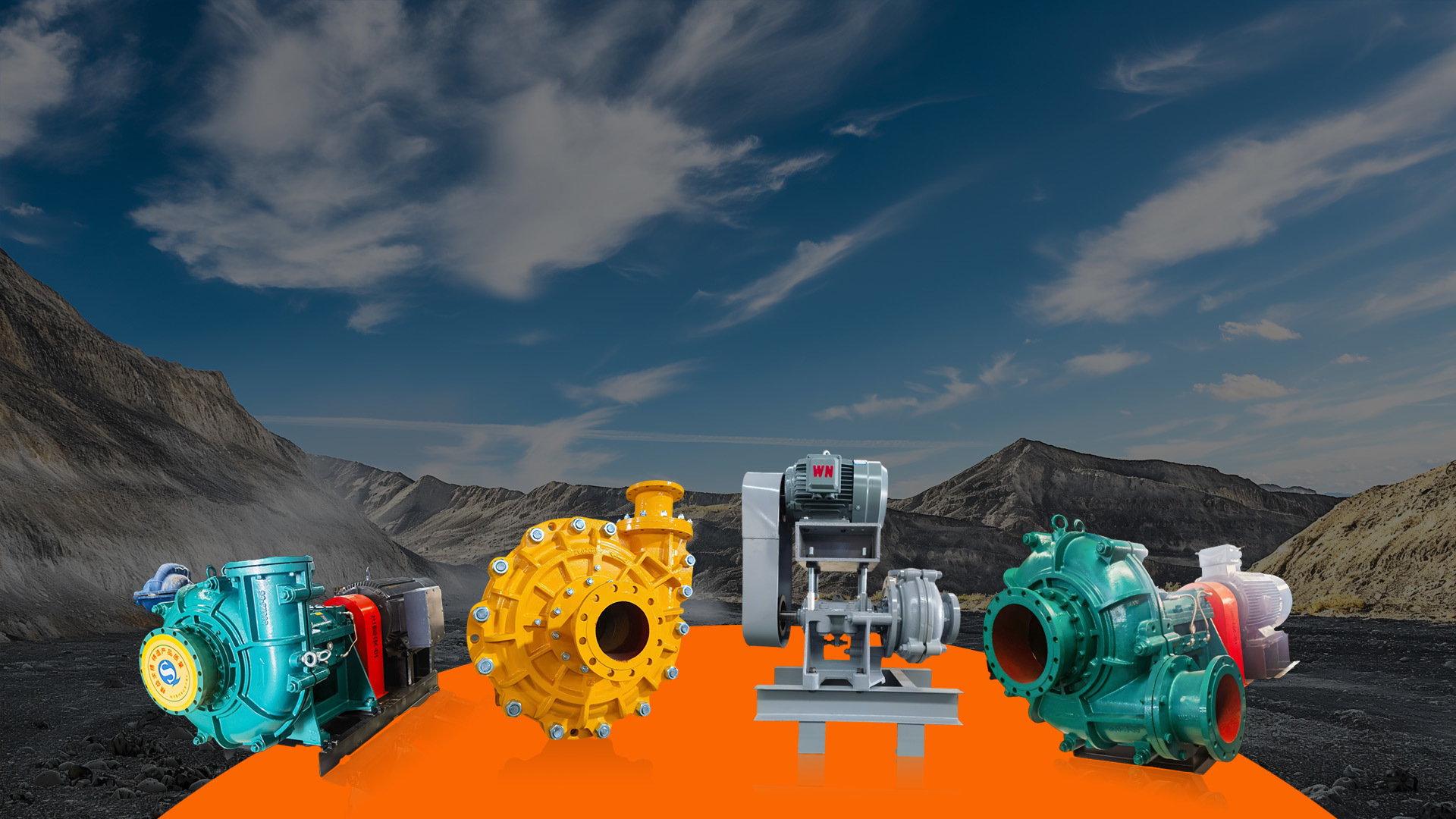

Powering the World with Precision Pumps

OUR PRODUCTS

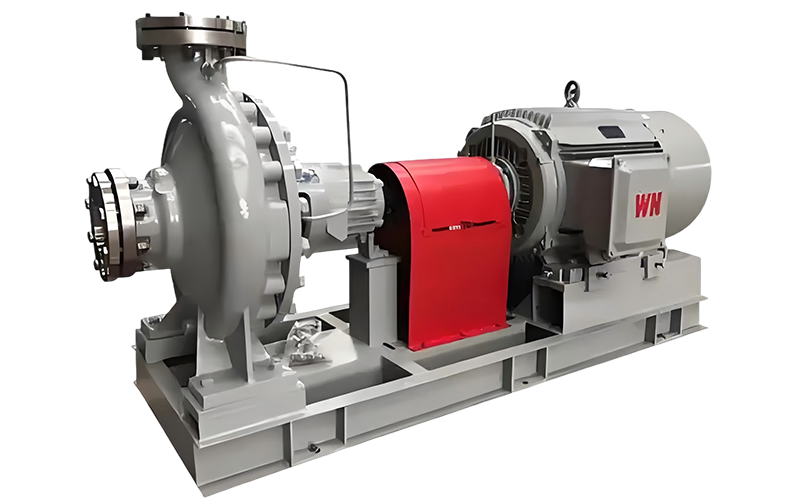

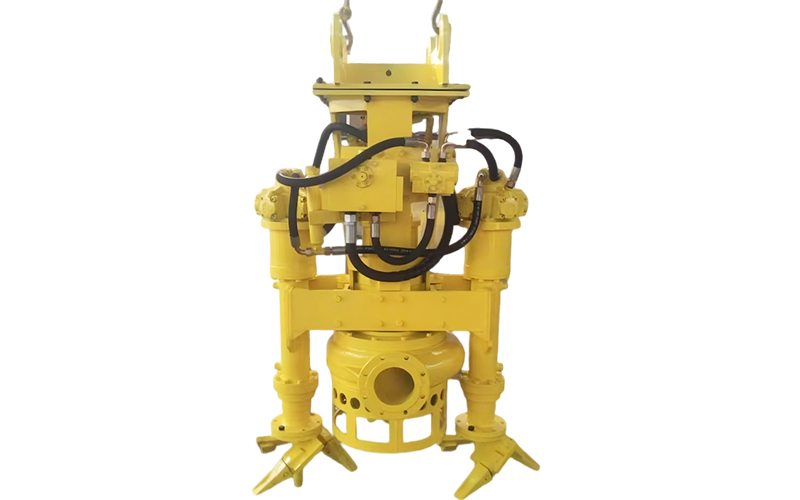

Explore high-performance dredging systems and slurry pump for efficient, reliable solutions

Find Your Pump →RDPUMP

Decades Of Expertise, Tailored Solutions

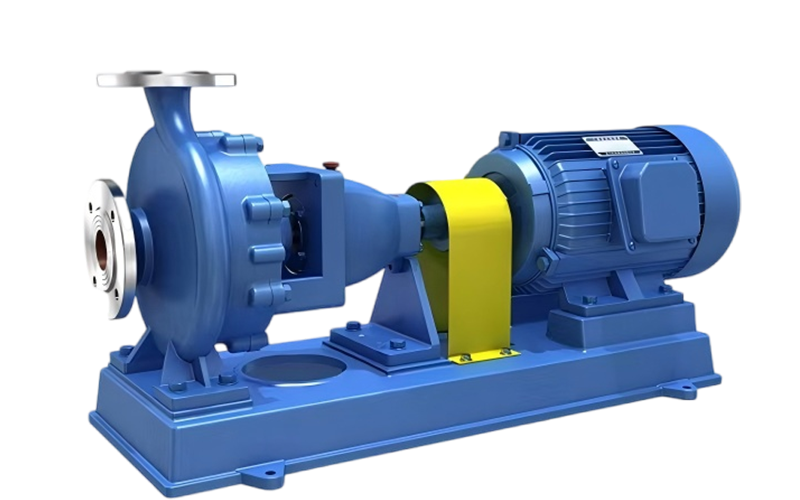

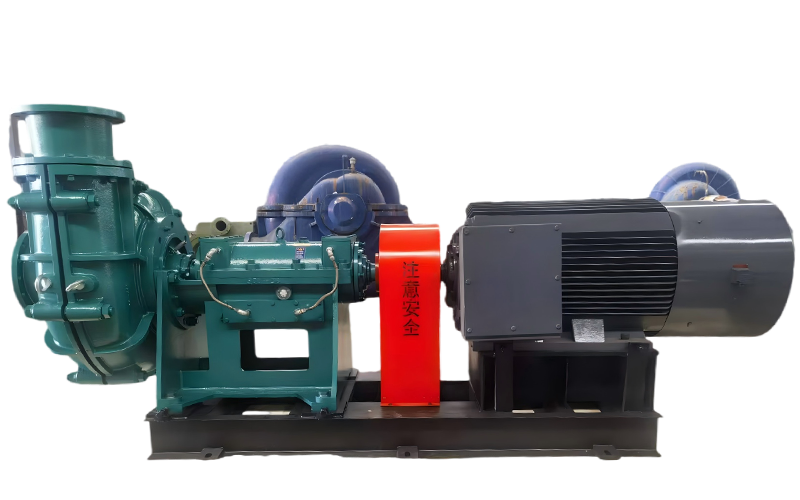

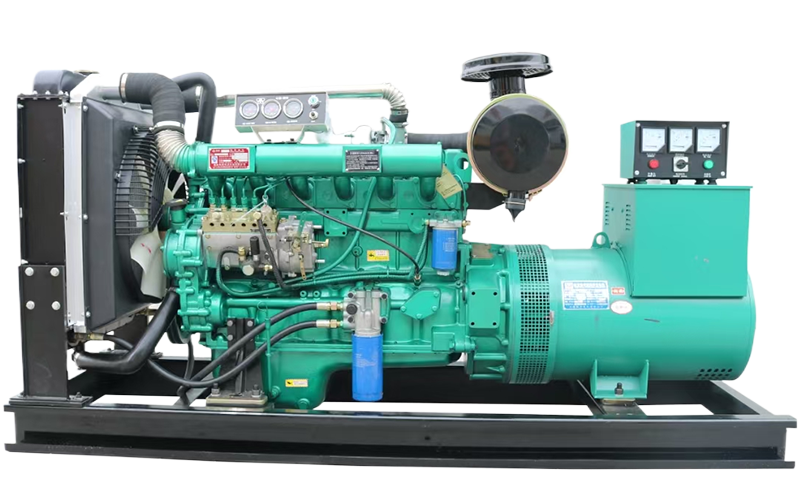

As a slurry pump manufacturer, we meet our customers’ diverse customization needs. Whether for mining, tunneling, metallurgy, dredging, or other specific working conditions, we tailor our products to meet the unique demands of each industry.

With advanced processing equipment and an experienced engineering team, we ensure the precise manufacture of components that meet our customers’ specifications. Whether it’s a large production run or a small order, we are committed to delivering high-quality products with on-time delivery.

INDUSTRIES & CUSTOM APPLICATIONS

Explore industry-specific solutions and custom applications for your project

All Applications →WELCOME TO RDPUMP

Decades Of Expertise, Tailored Solutions

Hebei Runda Pump Manufacturing Co., Ltd. is a professional manufacturer of integrated pumps integrating design, customization, production, manufacturing, sales and service. It has provided high-quality services to customers in many domestic and foreign industries such as coal, mining, smelting, electric power, petrochemical, urban sewage, etc., especially in slurry pumps, submerged slurry pumps, gravel pumps, mud pumps, desulfurization pumps, foam pumps, Lining pumps and other industrial pump series have become recognized as the leading brands in the industry. Main sales scope: China, North America, Japan, South America, the Middle East, Southeast Asia, East Asia, Oceania, Eastern Europe, Western Europe, Africa, etc.

Send an email to sales or support

Nearly Ten Years of Focus

Our Exploration Never Ceases

OUR ADVANTAGE

Your Reliable Pump Solutions Partner

The company passed the ISO9001:2000 quality management system certification, the establishment of a complete and strict quality control system. Starting from the procurement of raw materials, every link is strictly controlled to ensure that the materials used meet high quality standards and lay a solid foundation for the production of high-quality pumps. In the production process, the use of advanced testing equipment and scientific testing methods, detailed testing of each process, timely detection and resolution of possible quality problems.

Safe shipping

Seamless support, no language barrier

Safe shipping

Tailored to your needs

Safe shipping

Reinforced to prevent damage

24/7 support

Always here to help

Online guidance

Quick, expert assistance

Parts replacement

Fast and efficient

Flexible payments

30% prepaid option available

CLIENT TESTIMONIALS

DR Pumps perform best in harsh conditions because of our patented non-clogging design.

Emma Fischer

PumpsTech GmbH

Carlos Mendez

AgroFert S.A.

Rajesh Patel

Mumbai Infrastructure Ltd

Elevate your business with the state-of-the-art dredge pump engineering and slurry pump manufacturing company.

At RDPUMP Corporation, we promise innovative, reliable, and efficient pump solutions with exceptional service, ensuring optimal performance and minimal downtime in the most challenging environments.

BLOG & EVENTS

Pay attention to Runda and learn more about industry trends.

Apr 23,2025

Water pump blank from material selection to manufacturing process and quality control

dimensional accuracy Use a coordinate measuring instrument to detect key dimensions (such as pump body flow channel diameter, impeller inlet width) to ensure compliance with design requirements. For example, when producing gray cast iron parts in batches, a second level precision is taken with a margin of 4.0~5.0mm.

Apr 23,2025

The process of water pump processing

Preparation of raw materials: The structure of water pump parts is complex, with castings accounting for over 80%, mainly consisting of cast iron, cast steel, and cast stainless steel parts; There are few shaft components, mainly high-quality carbon steel, chromium steel or stainless steel parts. Select the appropriate blank manufacturing process based on the shape and material characteristics of the parts, such as casting, forging, or welding.

Apr 23,2025

The core process of water pump assembly

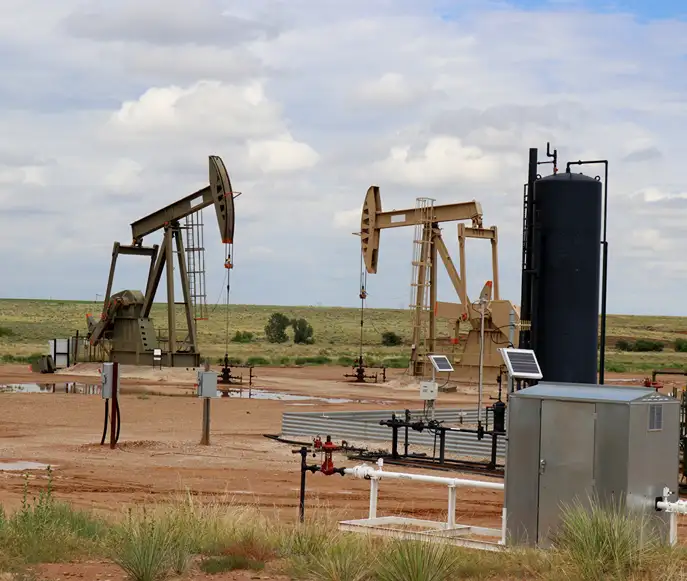

Slurry pumps are widely used in industries such as mining, power plants, metallurgy, chemical engineering, building materials, and petroleum.Preparation and Inspection of Components Rough machining: Mechanical machining such as turning, milling, drilling, etc. is performed on cast or forged pump bodies, impellers, pump covers, etc. to ensure dimensional accuracy (such as impeller diameter error ≤ 0.1mm).

Apr 23,2025

Application areas of finished water pumps

Application areas of finished water pumps: Agricultural irrigation: used for farmland irrigation, drainage, etc., to improve agricultural production efficiency.