Powering the World with Precision Pumps

Mine Tailings Pumping

Apr 27,2025

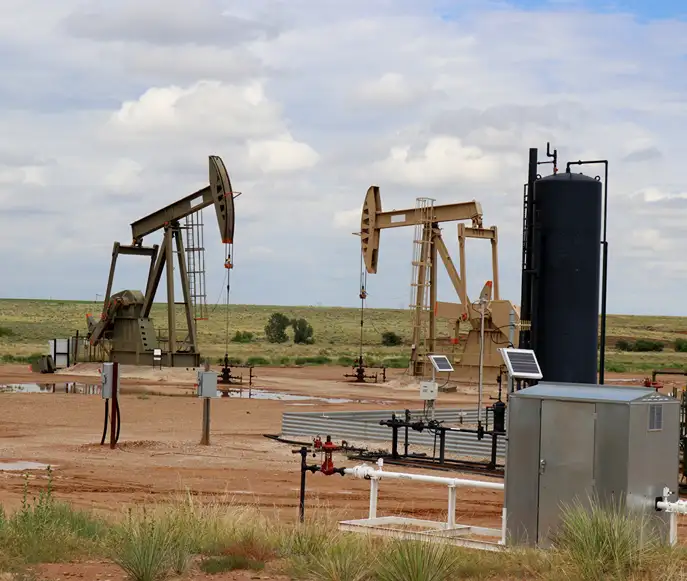

Mine Tailings Pump Applications

The mining industry incorporates various pumps in many applications to move slurries, mine tailings, and liquids from one part of the mine to another.

Typical Mining Pump Applications

• Mine Pits

• Tailings Ponds

• Poly-Lined Tailings Ponds

• Mineral Recovery

• Mine Dewatering

• Mine Sumps

• Process Pumps

• Mining (Pumping Target Material)

• Froth Flotation

Benefits of Using Mining Pumps

1. Time Efficiency

When you use an eddy pump to complete the mining process, you do not need to invest separate time in stopping the process and collecting the unwanted debris. The eddy/centrifugal mining pump — automatically pumps out the slurry from the hole that it digs. This debris is now transported via means of robust tubes to a location far away from the mining site. Therefore, you can efficiently mine for a larger time without stopping.

2. Cost Reduction

When you use a conventional boring or mining machine, you need to stop the procedure to collect the debris each time the mine is filled with it. After stopping the process, you need a method to collect the slurry and transport it out of the mine. Many mining operations typically either hire operators to use heavy material moving equipment or employ a conveyor belt to carry out the mine tailings removal process. Even after removing the mine tailings from the mine, you need to invest in hiring expensive bulldozers, excavators, and trucks to carry out the transport of spent material from the mine location to a disposal location.

3. High Resistance to Wear

After significant time and usage of traditional mining pumps, they tend to wear down quickly due to the harsh environment due to a combination of high abrasion, heat, and corrosion which are all commonly encountered with various types of mine tailings. The wear and tear process, over time, makes the volute or pump casing brittle and rapidly chews through impellers, causing the pump to drastically lose efficiency and creates costly downtime for maintenance and pump replacements. The wear and tear will get worse as more and more of the mine tailing material comes into contact with the impeller and other critical pump components.

Hot Tags:

PREVIOUS: