Powering the World with Precision Pumps

Frac Sand

Apr 27,2025

Frac Sand Pump Applications

With all sand and aggregate production, the key metric for producers is to operate while controlling the cost per ton to produce your end product. Our pumps will increase those operation efficiencies with lower maintenance and higher output.

• Mining the Frac Sand

• Frac Blending Rigs

• Discharging the Frac Sand

• Frac Sand Pumping Equipment

Frac Sand Mining

High production costs, coupled with rapid pump wear, are some of the main issues affecting the frac sand industry. As with all sand and aggregate production, the key metric for producers is to tightly control the cost per ton to produce the end product. New technologies can lessen the weight of operating costs for the life of your project, and knowing where to invest helps.

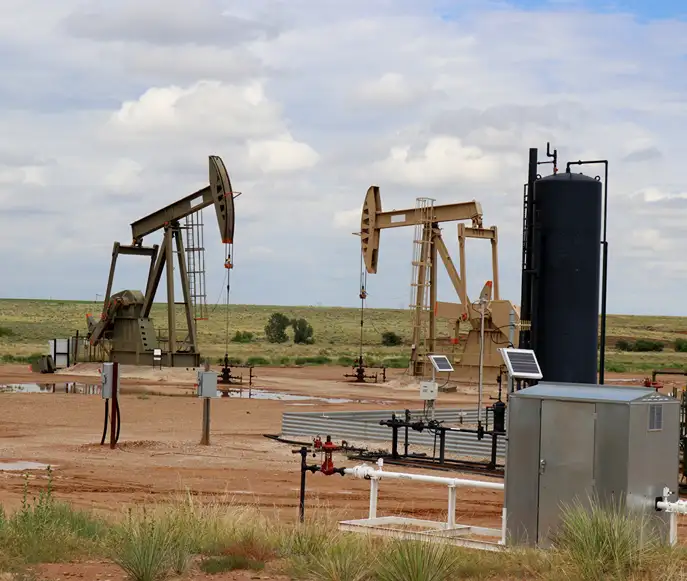

Frac Sand AKA hydraulic fracturing proppants, is a very abrasive type of sand that causes a plethora of issues for pumps in the frack sand mining and oil/gas industries. Initially, the frac sand is mined from pits and sandstone formations. Once mined, the sand is transported to fracking sites and often loaded into frac blender rigs. The frac sand is dumped into these large blender rigs which then mix the frac sand with chemicals such as hydrochloric acid and other components to get it ready for fracturing.

Frac Sand Blender Pumps & Blending Rigs

Once the frac sand has been loaded into the rig hopper (featured in the image), it is then conveyed into an onboard tank where chemicals and other additives are added to the frac sand and thoroughly mixed to a slurry-like state to prepare it for hydraulic fracking. Once the sand is fully blended and ready, it then needs to be pumped to the next station which utilizes high-pressure piston pumps to force the sand mixture into boreholes at extremely high pressures to crack open subterranean rocks and fissures.

In this image, frac sand is being introduced into the hopper of the frac sand blending rig, ready to begin the process of hydraulic fracking.

This transport process destroys conventional centrifugal pumps due to the abrasive nature of frac sand, costing downtime and lost money on frequent repairs. These pumps are usually driven hydraulically or by diesel depending on the Frac Blender Rig setup. There is also significant vibration that occurs on rigs that also can cause the pump to fail faster and the tolerances to get affected quicker. Frac sand can also be mechanically dredged up, but this is often very costly and typically inefficient for the purposes of frac sand mining.

As you can see, centrifugal impellers are quickly eroded when faced with the harsh abrasiveness of frac sand transmission through a pump with close critical tolerances. As a result, frequent maintenance and expensive spare parts are required to keep the pumps running, making critical components of centrifugal pumps used for frac sand applications.

Hot Tags:

PREVIOUS:

NEXT: