Powering the World with Precision Pumps

Oil & Gas / Drilling Mud

Apr 27,2025

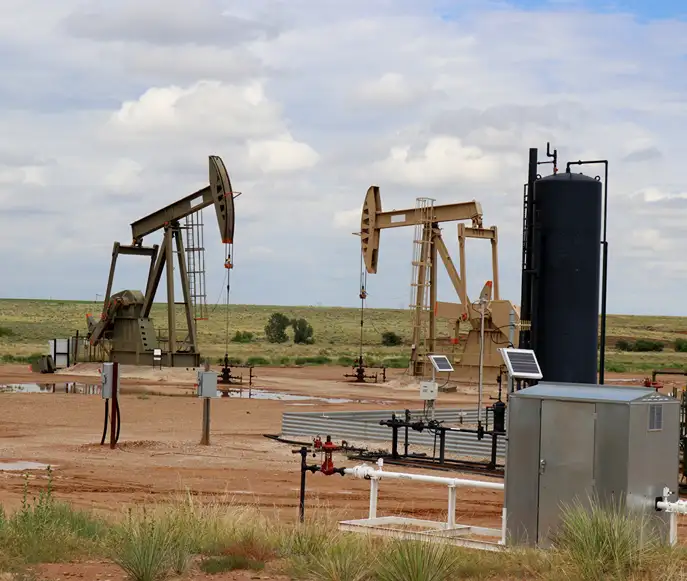

Oil and Gas Pump Applications

Drilling mud is the thick, viscous mud used in oil and gas drilling operations.

The Problems Associated With Current Methods of Processing Drill Cuttings

One of the most expensive and troubling issues with drilling operations is the handling, processing, and circulation of drilling mud along with disposing of the unwanted drill cuttings. The drilling cuttings deposited in the half round tank and are typically removed with an excavator which must manually move the drill cuttings out of the waste bin or roll-off box and into the truck. The excavators are usually rented for this duty and the equipment charges can range from $200-300/day. Add in the cost for the day and night manpower and the real cost for a single excavator can be as much as $1800/day.

Excavator safety issues. An excavator can be a safety concern and removing this unit can increase the safety profile along with reducing cost.

Using the excavator method explained above, the unloading of 50 barrels of drill cuttings from the half round can take as long as one to two hours. This task is mostly performed by the solids control technicians. The prime duty for the solids control technicians is to maintain the solids control equipment in good working order. This involves maintenance for the equipment, screen monitoring and changing, centrifuge adjustments, and retort testing to prepare a daily operational summary of the solids control program.

Operating the excavator takes the technician away from these tasks and can lead to poorly performing equipment. Additionally, the excavator has the potential for abuse as some solids control technicians use the climate-controlled cab as a break area or refuge from the elements. Many times, these guys are found asleep on the job.

One solids control company reported the idle time for the excavator can be more than 8 hours for a 24-hour period with 8 hours of operation and 8 hours of shut down time. Fuel and time lost can cause an economic drag on rig operations. And lastly, there have been several accidents on each rig causing a potential for injury, loss of production, and lost revenue as the excavator must be repaired.

Other Drilling Mud & Drill Cuttings Disposal Methods

Currently, most onshore drilling rigs dispose of drilling mud by mechanically loading the used drilling mud onto trucks via excavator or hire vacuum trucks to come and transport the mud away. Another method of disposal is by mechanically loading the drilling mud into poly-lined ponds until a threshold is met, before being trucked off for permanent disposal. Both these options are expensive and require a lot of manpower. Conventional pumps cannot move the drilling mud due to the high viscosity of up to 1000 cp and specific gravity of up to 1.9. This, along with the occasional large cuttings cause a nightmare for centrifugal pumps. Most pumps cannot even move the material and the ones that can have their impellers and volutes chewed up by the abrasive nature of the drilling mud, greatly shortening the lifespan of the pump which leads to frequent costly pump repairs coupled with unscheduled operational downtime.

Types of Drilling Fluids

Drilling fluids, also known as drilling mud, exhibit varying levels of abrasiveness and high viscosity. The three main types of drilling fluids are:

• Water-based mixtures — mud with the lowest opportunity for reclaim and recycling

• Synthetic drilling fluids — an advanced highly recycled oil blend primarily used on offshore drilling and dredging operations

• Oil-based mud — a standard petroleum mixture featuring plenty of clay and minerals in the forms of barite, lignite, and lime

Since oil and synthetic-based drilling muds feature a higher lubricity even at high temperatures and viscosity levels, they’re commonly chosen for dredging and drilling procedures with heavy levels of drill cuttings.

Mud cleaning systems such as mud shaker pumps and bentonite slurry pumps move the material over screens and through dryers and centrifuges to retrieve even the finest bits of stone and silt. However, the pump operators must still get the raw slurry to the drill cuttings treatment area with a power main pump. Slurry pumps designed around the power of an Eddy current offer the best performance for transferring cuttings throughout a treatment system.

Oil and Gas Pump Applications

• Mud Control for Drilling

• Oil Sand Extraction

• Drill Cuttings Transport/Disposal

• Oil Sumps

• Oil and Gas Web Brochure HERE

Hot Tags:

PREVIOUS:

NEXT: