Powering the World with Precision Pumps

Barge Unloading

Apr 27,2025

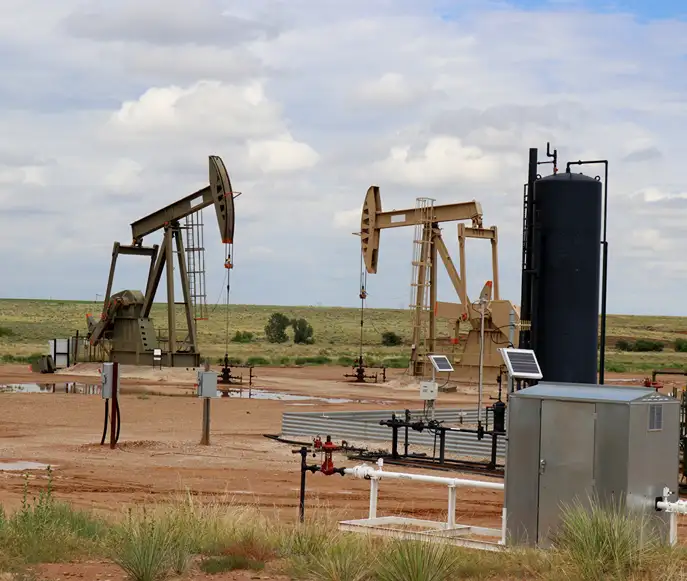

Common Barge Pump Applications

• Dredged Material Pumping

• Petroleum Distillates

• Chemical or Brine Removal

• Fertilizers, Oils, Molasses

• Sludge or Slurry Remediation

Problems With Barge Material Movement

Some types of slurry and abrasive materials wreak havoc on a regular pump. Centrifugal pumps quickly get worn down and lose their tolerances and suction capabilities. This results in significant downtime and costly spare parts. This is not the case with the EDDY Pump, it can take the abuse of abrasive materials because of its sunken rotor design. The eddy current of the pump whips material right past the rotor with minimal wear.

Excavator Dredge Pump Attachment

The liner-safe wheels allow the pump to easily glide over the liner without having any negative effect, while still removing all the fly ash. Slurry hose is then connected to the pump and run along the boom of the excavator over the back of the excavator and connected into pipeline. The pump can move material at rates of up to 400 cubic yards over distances of over a mile, at solids rates of 40-70%. This is all done creating little to no contaminant resuspension or detectable turbidity.

Applications: Rail Car and Barge Slurry Transport

The purpose of this page is to identify your application and learn more about an equipment solution to meet your needs. These are the most common barge transport applications that we work with. We are the OEM for the tools shown.

Application: Transport and pump material out of or into barges and rail cars.

Material: Slurry, wet grains, bottom material from environmental cleanup or any material with a wet format. This barge unloading dredger is Not for dry material transport.

Common Unload Scenario:

The EDDY Pump Excavator Attachment is ideal for pumping slurry from barges, rail cars, pits, lined ponds or other bodies used for material storage.

By attaching the EDDY Pump to a standard boom or long boom excavator you can get reach of up to 75-ft and handle the most difficult applications. The EDDY Pump allows you to pump the fly ash at distances over 2-miles at production rates of up to 600 tons of ash per hour or 5000 GPM.

Optional upgrade: Add liner-safe rollers, as it also gives you the ability to dredge on concrete lined sumps or poly-lined reservoirs without disturbing the liner.

Below are common pumping distances we see, along with a pump curve to match the details. Contact us with your exact numbers.

Hot Tags:

PREVIOUS:

NEXT: