Powering the World with Precision Pumps

Apr 23,2025

Water pump blank from material selection to manufacturing process and quality control

dimensional accuracy Use a coordinate measuring instrument to detect key dimensions (such as pump body flow channel diameter, impeller inlet width) to ensure compliance with design requirements. For example, when producing gray cast iron parts in batches, a second level precision is taken with a margin of 4.0~5.0mm.

Apr 23,2025

The process of water pump processing

Preparation of raw materials: The structure of water pump parts is complex, with castings accounting for over 80%, mainly consisting of cast iron, cast steel, and cast stainless steel parts; There are few shaft components, mainly high-quality carbon steel, chromium steel or stainless steel parts. Select the appropriate blank manufacturing process based on the shape and material characteristics of the parts, such as casting, forging, or welding.

Apr 23,2025

The core process of water pump assembly

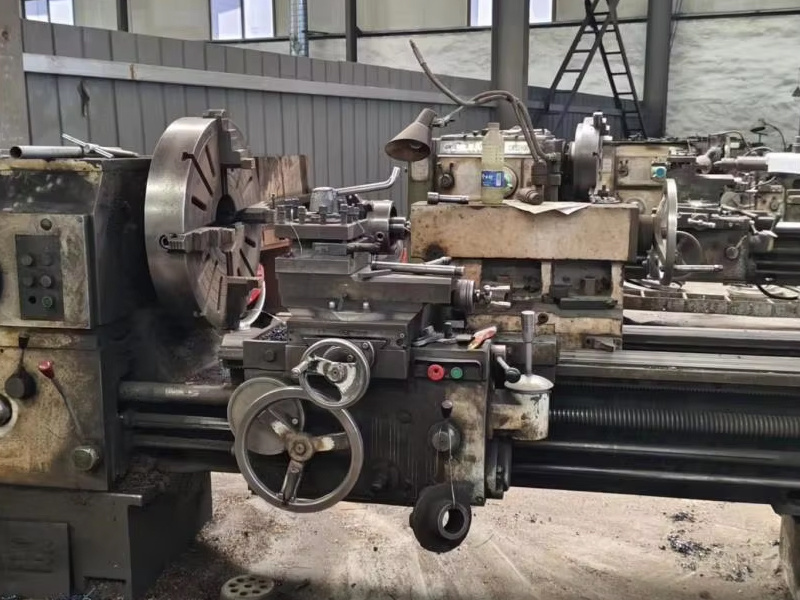

Slurry pumps are widely used in industries such as mining, power plants, metallurgy, chemical engineering, building materials, and petroleum.Preparation and Inspection of Components Rough machining: Mechanical machining such as turning, milling, drilling, etc. is performed on cast or forged pump bodies, impellers, pump covers, etc. to ensure dimensional accuracy (such as impeller diameter error ≤ 0.1mm).

Apr 23,2025

Application areas of finished water pumps

Application areas of finished water pumps: Agricultural irrigation: used for farmland irrigation, drainage, etc., to improve agricultural production efficiency.

Apr 23,2025

The working principle of a double suction pump

It is mainly based on pressure difference and centrifugal force. When the double-suction pump starts working, both of its inlets will form a negative pressure area, and the liquid will be driven by the pressure difference to flow from the supply system to the pump's suction inlet.

Apr 23,2025

Precautions when using sewage pumps

When using a sewage pump, ensure it is installed correctly and securely to avoid vibrations and noise during operation.

Apr 23,2025

Water pumps have a wide range of applications in various fields.

Agricultural irrigation: Extracting groundwater or river water sources for irrigation. Construction engineering: Used for concrete delivery, building drainage, fire protection systems, etc.

Apr 23,2025

When selecting a water pump, the following points should be considered.

Determine flow rate: Calculate the flow rate based on the specific needs for water usage or liquid transportation. Determine lift: Calculate the vertical height from the water source to the destination, considering pipeline resistance loss.

Apr 23,2025

Keep the equipment clean, dry, free of oil stains, and without leaks. Regularly check the operating sound, vibration, and leakage of the pump.

Apr 23,2025

A water pump is an important fluid transport device, widely used in various fields.

The water pump transmits the mechanical energy of the prime mover or other external energy to the liquid, increasing the energy of the liquid. It is mainly used to transport liquids including water, oil, acidic and alkaline liquids, emulsions, suspensions, and liquid metals. It can also transport liquid-gas mixtures and liquids containing suspended solids.

Contact Us

E-mail:

Phone/WhatsApp:

Address:

Shifo Town, Anguo City, Baoding City, Hebei Province, China