Powering the World with Precision Pumps

Process Pump

Apr 27,2025

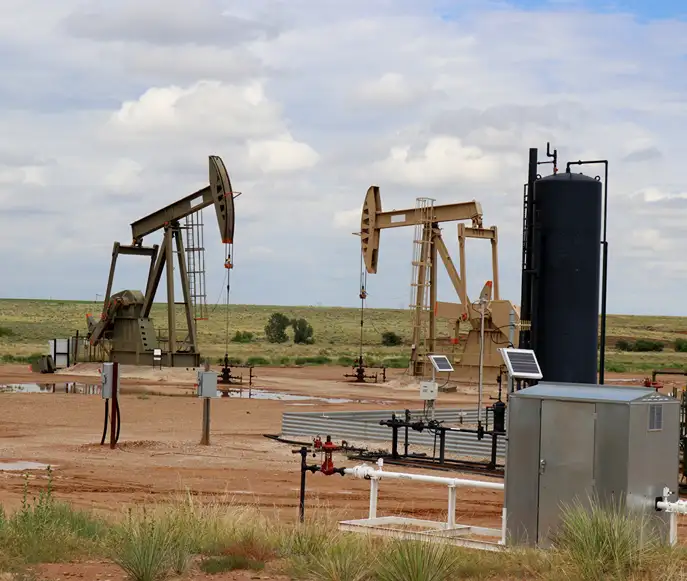

Process Pump Applications

Process pumps are designed to move fluids, slurries and other liquid materials from one part of the site to another.

Process Pump Applications

• Process Pumps

• Foundry Waste / Mill Scale

• Manufacturing

• Sump Cleanouts

Process Pumping Problems

Process pumps are found in various industries and are typically built and utilized for a specific purpose. They can also be found at many different stages throughout the entire industrial process, often employed to pump difficult materials that can routinely cause problems for the pump (including cavitation and seal failure) process, which, in turn, affects the entire operation.

Factories, chemical and processing plants, and manufacturing centers all need reliable, specialized process pumps. These specialized ANSI process pumps are available in two main types, including positive displacement and centrifugal pumps (usually equipped with check valves to prevent flow reversal). The selection of a process pump heavily depends on the process, temperature, pressures and the type of material or fluid the pump will handle.

For highly abrasive and viscous material, a centrifugal pump would have frequent maintenance problems, including clogs, seal failure and impeller wear. As a result, the best type of ANSI process pump over a centrifugal pump for this highly abrasive and viscous material would be a heavy-duty EDDY Pump or potentially other positive displacement pump.

Process pumps play a critical role in ensuring the smooth operation of industrial processes. The ANSI process pumps are engineered to handle various materials with specialized impellers, from fluids to slurries, and each type is specifically designed to meet or exceed a range of needs, like low flow, high flow, etc. In industries such as chemical processing, pharmaceuticals, food and beverage, and wastewater treatment, the reliability of process pumps is paramount. These ANSI process pumps must endure harsh conditions, and challenging materials without compromising efficiency or performance, which is why they are heavily favored in the oil and gas sectors.

Different types of ANSI process pumps offer unique advantages. Positive displacement pumps, for example, are ideal for handling viscous and abrasive materials. They operate by trapping a fixed amount of fluid and displacing it through the pump, making them highly effective for consistent flow rates. Centrifugal process pumps, on the other hand, use a rotating impeller or radial vane impeller to impart velocity to the fluid, converting it into flow. While centrifugal pumps are widely used for their simplicity and efficiency, they may not be suitable for highly viscous or abrasive materials. Positive displacement pumps, meanwhile, are key for high pressures and low flow, controlled processes.

Process Pumping Scenario

Typical Process Pump Applications:

• Process Pumps

• Foundry Waste / Mill Scale

• Manufacturing

• Sump Cleanouts

The purpose of this page is to identify your application and learn more about an equipment solution to meet your needs. These are the most common process and manufacturing pump applications that we work with. We are the OEM for the tools shown.

Hot Tags:

PREVIOUS:

NEXT: